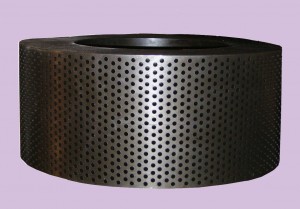

Since the beginning of ’50 years, when appeared first models of pellet mill machines, dies always have been and still are considered the most important spare, that must be present at anytime on the stock of the pellet mill end user. Belong the years ring dies have been developped and changed, both on the shape and on the dimensions too. Initially built on case-hardening steel only, step by step they gradually have been substituted by stainless steel type, under vacuum tempered. The extreme hardness reachable with that heat treatment is not limited to the die surface only, since it comes to material heart too. This type of high chrome stainless steel grants to the die a long lifetime and the constant production of very good pellet. With the rare exception of few particular sectors only, today all pellet mill end users just prefer stainless steel dies heart tempered, made on under vacuum controlled atmosphere.

To grant optimum pellet production, all ring dies must present the holes location executed upon the principle of equilateral triangle. On a few words the space between the holes, both located on columns and on line, always must be constant. On that way it is indispensable the use of very special and automatic drilling units (gun drilling machines), operating at very high speed. Every special drilling tool almost works on absence of vibrations, so that roughness of the hole inside surface results extremely low. EOS got a lot of quoted drawings of the main pellet mill producers (Buhler, CPM, Kahl, Lamec, MTD, Paladin, Mabrik, Matador, Muench, Sprout Waldron, Stolz, Swiss Combi, Tekno Uno, UMT, Van Aarsen), since we deal all main spares and wearing parts for such kind of machines, naturally also included the roll shells.

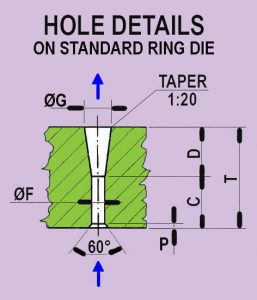

MAIN TECHNICAL TERMINOLOGY ABOUT RING DIES

|

F = HOLE DIAMETER. The dimension of the cylindrical hole corresponds to the diameter of the pellet produced by the die. T = DIE THICKNESS. Variable upon type of the press and especially upon the kind of product to be pellettized, never it results shorter than 30 mm. On the spares called passing hole dies (side to side) or dies without any kind of counterbore, it corresponds to the value of the die compression too. D = COUNTERBORE DEPTH (or free pellets discharging zone). It is considered the difference between the die total thickness and its net compression. It must be always indicated while the die should be built with counterbore, usually with fix taper value 1/20 or just sometimes only with cylindrical counterbore type. |

C = NET DIE COMPRESSION. Strictly bond to the hole diameter, net compression is variable upon type of product to be pellettized too. Die compression also includes the entrance cone depth and corresponds to the cylindrical portion of the hole, where the product is pressed and where the pellet is formed. On the dies called passing hole dies (side to side) or dies without any kind of counterbore, it corresponds to the value of the total thickness too.

G = COUNTERBORE BASE DIAMETER. Irrelevant to the productive scope, it is indicated just for the correct dimension during the die planning step. Just in case of cylindrical counterbore dies, that today result rarely adopted because considered an old concept and not used anymore, counterbore base diameter corresponds to the same counterbore dimension.

P = ENTRANCE CONE DEPTH. With the exception of very rare cases, the entrance cone always is 1,5-2,0 mm. deep and the funnel inclination is 60°.

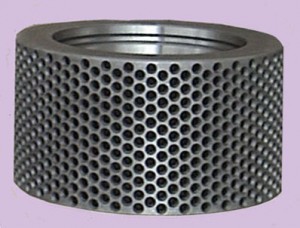

MAIN CHARACTERISTICS OF THE ROLL SHELLS

By the words “roll shell” is intended the outside cylindric surface of pressing roller, the spare part mainly subjected to the wearing. Shape and dimensions of the roll shells are variable, upon type and model of the pellet mill. Anyhow EOS got all quoted drawings necessary to fullfill the production of the roll shells for all main pellet mills present on the market worldwide.

Concerning the outside surface of the shells, that is available on 5 different versions: